Add to Cart

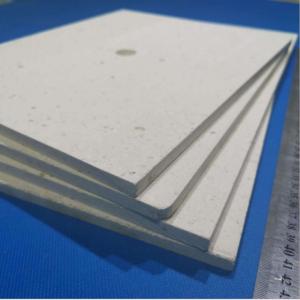

Description of corundum mullite ceramic setter plate

Main characteristics of the ceramic setter plates

1. High melting point, up to 1850℃

2. High service temperature, up to 1800℃

3. Low thermal expansion coefficient: 5.3×10-6

4. Good flatness with uniform shrinkage at the firing process

3. Chemical stability, even in a harsh environment.

4. Minimal warpage, bending, and undulation.

7. Excellent resistance against oil and chemical.

8. Stable breaking strength, and less variance in shape or dimensions.

Specification of ceramic setter plates

● Materials: corundum mullite, cordierite, high purity alumina, silicon carbide

● Dimensions: Side length max. 800mm x 500mm, Thickness can be 0.2mm to 30mm

● Surface treatment: fine ground, well-polished, lapping

● The checklist of standard size with the stock in corundum mullite as below

| S/N | Length(mm) | Width(mm) | Thickness(mm) |

| 1 | 150 | 150 |

Range from 2mm to 30mm |

| 2 | 150 | 300 | |

| 3 | 150 | 320 | |

| 4 | 240 | 120 | |

| 5 | 250 | 250 | |

| 6 | 295 | 295 | |

| 7 | 300 | 300 | |

| 8 | 310 | 310 | |

| 9 | 320 | 320 | |

| 10 | 330 | 330 | |

| 11 | 340 | 340 | |

| 12 | 650 | 500 |

★ 10+ Years of manufacturing experience in OEM, ODM ★ Powerful R&D, mass production capability

★ In-house comprehensive manufacturing types of equipment ★ Rigorous quality control system and processes

★ Surpassing pre-sales and after-sales service ★ Abide all orders as the first priority

FAQs (Frequently Asked Questions)

Q1: Do you send a sample to check?

A: Sure, the sample is free and freight collect.

Q2. Are you a factory or trading company?

A: We are a manufacturer. You are welcome to visit our factory.

Q3: When will you ship it?

A: If the products are in storage, we'll ship within 48 hours

Q4: When can I get the price?

A: We regularly quote within 24 hours after we get your inquiry. If you are in urgent need of getting the price.

Please call us or tell us in your email so that we will proceed with your inquiry as a priority.

Q5: Is it available to provide customized products?

A: We always support custom-made demand as per different materials, dimensions, and designs.

Q6: How to ensure quality?

A: The dimension out of any batch will be carried out sampling inspection per international AQL standard. A 100% cosmetic inspection will be done.

Q7: What other products are you dealing with?

A: We focus on a variety of ceramic tubes, ceramic substrates, ceramic sheets, textile ceramics besides ceramic setter plates.